A premise: there is a lot of talk about quality, maybe too much, but often it is only a word enable to fascinate the client: we try to achieve it during our activity. No business can product with zero defects, but surely we do our best to reduce to a minimum our non-conformity.

The targets of our quality policy:

Guidelines of the business quality policy formally defined by the management are the following:

- To reach top positions through the ability to supply products obtained by surface treatments, that can be a reference point in our marketplace segment.

The priority of our society is to provide products of reliable, consistent and traceable quality, on time and with the best satisfaction of the customer, and not surrender to any compromise for what concerns to the quality and reliability of the products supplied.

Our organization must ensure that the fulfillment of commitments is fast, efficient and economy, that any complaint receive a complete answer, and must ensure that the processes will be carried out with the same professionalism, seriousness and competence for all customers. - To achieve these objectives the company must pursue a process of constant improvement of its organization, applying corrective and preventive measures and involving in its quality policy all employees at any level and the suppliers.

- The Quality System adequacy and its efficacy over time are systematically exposed to Internal Audits to highlight the level of implementation of the policy and to identify appropriate corrective actions and improvements.

(Extract from the Quality Manual - Ed. 20/05/2010).

Here is a summary of how we handle your consignment material:

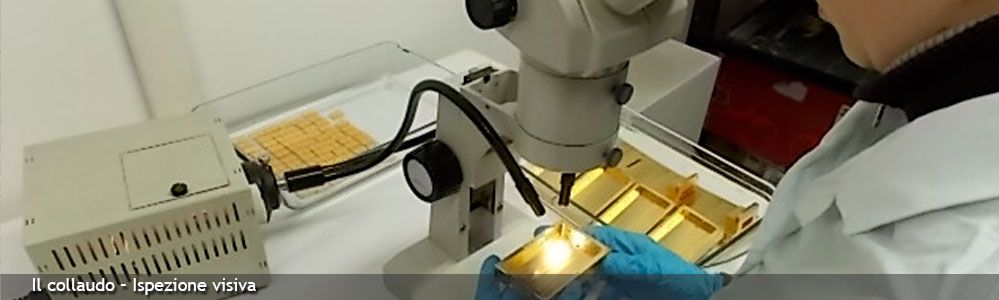

- Visual inspection of the material received: advisory to the customer of any defects which may affect the correct functionality of the object after the treatment, and then possible corrective actions are planned.

- Control of the accuracy of the received documentation (drawings, specifications of treatment...)..

- Compilation of a processing evaluation where the object is identified, the required treatment is indicated and the main steps of the process are described, including thermal controls and tests, with reference to the processing procedure concerning the treatment.

- Delivery of the material and documentation to the concerned production line: the operator shall affix his stamp/signature on the ballot, near the completed process steps.

- Control of the various parameters (thickness, adhesion, any thermal test, final visual inspection); the inspector shall affix his stamp/signature on the ballot, near the completed process steps.

- Packaging according to the instructions explained in the appropriate procedure, seek to ensure the integrity of the object during transport.

The measuring and monitoring equipment

The quality of processes and treatments performed is ensured through a number of tools which are regularly tested for their calibration status, through SIT centers or internal methods based on reference samples, in turn certificated.

• Thickness measurement – We have a series of tools that allow the measurement with four different methods, allowing control on a wide range of combinations between the deposited layer and the substrate/base material, the whole thing with non-destructive methods.

• X-ray fluorescence method, which measures the thickness of a wide range of combination galvanic layer/base material and also allows to recognize the various types of metal alloys.

• Magnetic induction method for the measurement of non-magnetic layers on magnetic metals.

• Method based on eddy currents for the measurement of non-conductive layers on conductive bases (anodic oxidation of aluminum, paint on metal bases).

• Method with beta rays, is a good complement to the X-ray instrument: it allows to measure in several cases higher thicknesses or to take measures on large objects.

Visual controls – from simple viewers 4X to 40X stereo microscope: they allow to identify defects that escape from a simple inspection by eye. With the aid of a high resolution camera you can be documented about the defects found.

Galvanic baths controls – A chemical laboratory in the company allows to keep under control in real time the electrolytic solutions and immediately make the necessary corrections.

The instrumentation consists of pH-meters, analytical balance, kits for the Hull cell, instrument with selective electrodes for the measurement of items present in small quantities (for example Chlorides), kit for analysis by electrolytic deposition on the platinum cathode and successive weighing, glassware and reagents for acid/base analysis, redox and iodometry.

More sophisticated controls are carried out externally at qualified laboratories.

Other instrumentation for process control – current clamps for periodic testing of current rectifiers and constant control during the production of small objects.

Temperature recorders: with 12 inputs for the periodic testing of dehydrogenation furnace and thermal test + 1 input recorder for routine control of the dehydrogenation and thermal cycles, with the possibility to download with a PC and print the related diagram.

IT

IT  EN

EN